Main Article Content

Abstract

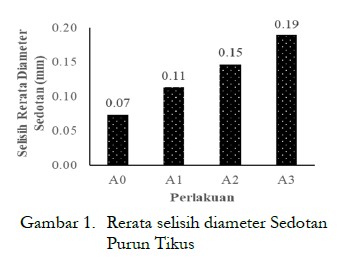

The edible coating is a natural layer that forms directly on the surface of a product and is safe to consume, as it is made from natural ingredients. Its primary purpose is to extend the product's shelf life while inhibiting physical, chemical, and biological changes. This research aims to evaluate the effects of various concentrations of chitosan in the development of edible coatings and to identify the optimal concentration for making these coatings from cassava starch, specifically for use on eco-straw water chestnuts. The study employed a Randomized Block Design (RBD) with four different treatment levels and three replications for each chitosan concentration: 0% (A0), 2% (A1), 4% (A2), and 6% (A3). The parameters measured in this research included straw diameter, water resistance, weight loss, water vapor transmission rate, and hue. The collected data were analyzed using Analysis of Variance (ANOVA) to determine the significance of each treatment and to identify the best-performing configuration. The findings indicated that variations in chitosan concentration significantly influenced water resistance (ranging from 80.25% to 94.92%), weight loss (from 1.24% to 6.05%), and water vapor transmission rate (between 2.48 and 7.11 grams/hour·m²). Conversely, the differences in straw diameter (from 0.07 mm to 0.19 mm) showed comparable values across treatments. The most favorable results were observed in treatment A3, which utilized a chitosan concentration of 6%.

Article Details

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.